- Mensajes: 2

- Gracias recibidas: 5

Manuales de Mecánica

Todo sobre la mecánica y noticias tecnológicas.

Manuales de Mecánica

Todo sobre la mecánica y noticias tecnológicas.

Buscar en MDM

Boletín

Alternador que no carga, Vin del rotor ?

- manual-mecanica

- Autor del tema

- Fuera de línea

- Fresh Boarder

-

Menos

Más

14 años 2 meses antes - 14 años 2 meses antes #28291

por manual-mecanica

Hola, se me ha encendido el piloto de indicador de carga de un Nissan MIcra antiguo, unos 10 años, es el de 1000cc y 60Cv. Verificado la bateria no ser recarga.

Hola, se me ha encendido el piloto de indicador de carga de un Nissan MIcra antiguo, unos 10 años, es el de 1000cc y 60Cv. Verificado la bateria no ser recarga.

Como soy electricista, tengo algunas nociones,y voy a ver si puedo resolver el problema sin tener el manual a mano, asi que, he quitado el alternador y lo he desmontado.

Los bobinados están "bien", ni abiertos ni tienen corrientes de fuga. Las escobillas bien tb.

Entonces, como no puedo llegar a los diodos facilmente, he dibujado un rectificador trifasico de 6 diodos, he medido los 3 que van al positivo de bateria , los 3 bien, dan 534 seleccionando la medida de diodos . Los 3 que van de negativo a las fases bien tb, 534, en los 6 casos , polarizados inversamente no dan valor, la pantalla del polimetro se queda en 1.

Además, en el alternador hay un conector doble con 2 terminales de cuchilla como tipo faston.

, uno de ellos debe ser el de carga porque luego en la istalacion electrica es el que va al fusible de 10A , ademas viene de las fases, pero hay intercalado entre fase y terminal algún semiconductor, porque me da un valor de 1040 si lo mido con el selector en medida de diodos, inversamente da 1704.

las escobillas alimentadas a traves del positivo cable gordo directamente una de ellas, , y la otra a traves de las fases con semiconductores intercalados tb.

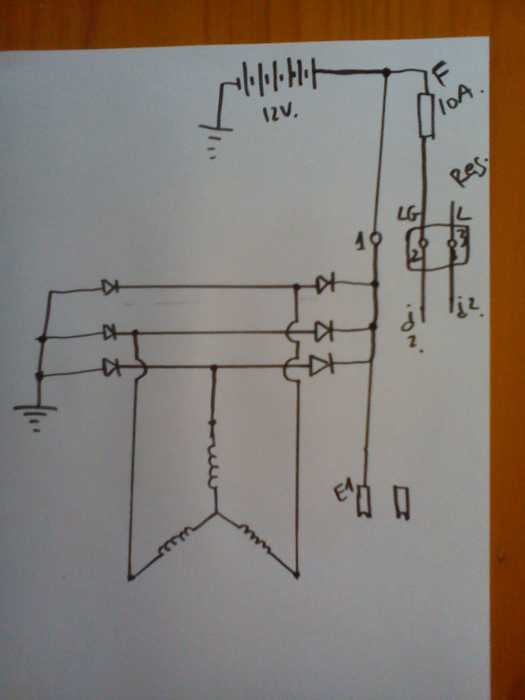

Bueno os he hecho un esquema a ver si me podeis dar algo de luz, mas que nada saber si esta bien el alternador, o si teneis algun esquema.

Ah el otro terminal del conector me tienen confundido, y en la instalacion no se donde va, los demás bien, uno al fusible de 10A y el otro directo bateria, continuidad bien. El fusible de 10A OK.

Muchas gracias, y a ver si me podeis orientar un poco, y descubrir el porque de que no cargue.

A ver si lo puedo solucionar y no tenerme que gastar un paston o tirar el coche al desguaze.

Un saludo

Alternador que no carga, Vin del rotor ? Publicado por manual-mecanica

Archivo adjunto no encontrado

Como soy electricista, tengo algunas nociones,y voy a ver si puedo resolver el problema sin tener el manual a mano, asi que, he quitado el alternador y lo he desmontado.

Los bobinados están "bien", ni abiertos ni tienen corrientes de fuga. Las escobillas bien tb.

Entonces, como no puedo llegar a los diodos facilmente, he dibujado un rectificador trifasico de 6 diodos, he medido los 3 que van al positivo de bateria , los 3 bien, dan 534 seleccionando la medida de diodos . Los 3 que van de negativo a las fases bien tb, 534, en los 6 casos , polarizados inversamente no dan valor, la pantalla del polimetro se queda en 1.

Además, en el alternador hay un conector doble con 2 terminales de cuchilla como tipo faston.

, uno de ellos debe ser el de carga porque luego en la istalacion electrica es el que va al fusible de 10A , ademas viene de las fases, pero hay intercalado entre fase y terminal algún semiconductor, porque me da un valor de 1040 si lo mido con el selector en medida de diodos, inversamente da 1704.

las escobillas alimentadas a traves del positivo cable gordo directamente una de ellas, , y la otra a traves de las fases con semiconductores intercalados tb.

Bueno os he hecho un esquema a ver si me podeis dar algo de luz, mas que nada saber si esta bien el alternador, o si teneis algun esquema.

Ah el otro terminal del conector me tienen confundido, y en la instalacion no se donde va, los demás bien, uno al fusible de 10A y el otro directo bateria, continuidad bien. El fusible de 10A OK.

Muchas gracias, y a ver si me podeis orientar un poco, y descubrir el porque de que no cargue.

A ver si lo puedo solucionar y no tenerme que gastar un paston o tirar el coche al desguaze.

Un saludo

Última Edición: 14 años 2 meses antes por .

Por favor, Conectar o Crear cuenta para unirse a la conversación.

- manual-mecanica

- Autor del tema

- Fuera de línea

- Fresh Boarder

-

Menos

Más

- Mensajes: 2

- Gracias recibidas: 5

14 años 2 meses antes - 14 años 2 meses antes #28300

por manual-mecanica

Respuesta de manual-mecanica sobre el tema Re: Alternador que no carga

Jose Luis, los diodos entiendo que los has medidido poniendo los cables en ambos extremos de cada elemento, pero has medido si hay continuidad de la conexión del diodo a la placa. Yo reparé una placa de diodos de un alternador de un 505, a simple vista no se notoba pero se le había ido la soldadura a uno y no pasaba corriente, ten en cuenta que donde va montado hay mucha temperatura y son diodos grandes que tienen mucha intensidad y terminan jodiendo las soldaduras. Suerte.

Otra cosa que se me olvidaba, en los alternadores tienes aparte de la placa de diodos el regulador de carga, será el otro circuito que dices del conector doble. Es el encargado de meter mas o menos corriente al rotor para aumentar o disminuir el campo magnético según se necesite mas o menos corriente. Osea es el encargado de que la salida sea siempre 13,6V independientemente se la carga que tenga el circuito mas luces, A.A., luna térmica... etc.

Creo que la salida eran 13,6V pero no estoy seguro, ademas puede variar según modelos.

El regulador de carga es mas dificil de reparar, la placa de diodos si la puedes reparar pero el regulador creo que no.

De todas formas la placa yo la soldé con un soldador de 150 W y en vez de meterle estaño normal le metí estaño plata, del que usan en fontanería, tiene un punto de fusión mas elevado. Ya te dije que el problema es la temperatura. Tampoco calientes demasiado los diodos si tienes que repasar alguna soldadura porque te los cargas, osea el soldador a tope y un pico de calor rápido desde que acercas hasta que funde.

Otra cosa que se me olvidaba, en los alternadores tienes aparte de la placa de diodos el regulador de carga, será el otro circuito que dices del conector doble. Es el encargado de meter mas o menos corriente al rotor para aumentar o disminuir el campo magnético según se necesite mas o menos corriente. Osea es el encargado de que la salida sea siempre 13,6V independientemente se la carga que tenga el circuito mas luces, A.A., luna térmica... etc.

Creo que la salida eran 13,6V pero no estoy seguro, ademas puede variar según modelos.

El regulador de carga es mas dificil de reparar, la placa de diodos si la puedes reparar pero el regulador creo que no.

De todas formas la placa yo la soldé con un soldador de 150 W y en vez de meterle estaño normal le metí estaño plata, del que usan en fontanería, tiene un punto de fusión mas elevado. Ya te dije que el problema es la temperatura. Tampoco calientes demasiado los diodos si tienes que repasar alguna soldadura porque te los cargas, osea el soldador a tope y un pico de calor rápido desde que acercas hasta que funde.

Última Edición: 14 años 2 meses antes por . Razón: Faltaban datos

Por favor, Conectar o Crear cuenta para unirse a la conversación.

- manual-mecanica

- Autor del tema

- Fuera de línea

- Fresh Boarder

-

Menos

Más

- Mensajes: 2

- Gracias recibidas: 5

14 años 2 meses antes #28304

por manual-mecanica

Respuesta de manual-mecanica sobre el tema Re: Alternador que no carga

no es lo mismo la electricidad industrial y la automotriz. Este tipo de alternador tiene una nomenclatura del conector, la IG y L estas son ignicion que viene de un fusible y la L que es luz piloto y va directo al tablero casi siempre. Tu esquema esta mal. Los 3 diodos que van a un carbon son la alimentacion positiva de la masa y la negativa la genera el regulador de voltage. La linea del tri diodo que va al carbon esta creo que in directamente unida a la luz piloto y eso es lo que enciende la luz y se apaga cuando esta se vuelve positiva, cuando genera el alternador. enciende porque el negativo generado por el regulador circula por la masa y dentra al otro carbon para alimentar la luz en el tablero y el foco en el tablero esta unido al otro extremo con el fusible de los marcadores. Sin la exitacion positiva de la luz piloto el alternador no carga y lo contrario sin el voltage que sale de los 3 diodos a la escobilla no carga ni apaga el piloto. si no te apaga el piloto tienes problemas o con el tri diodo, o con el regulador. todos los reguladores de voltage vienen regulados a 14.4 voltios no a 13.6 lo que los hace bajar es el consumo al sobre cargar el sistema con extras que no son del vehiculo, una bateria defectuosa, o falsos contactos y se llaman caidas de tension la mayoria revisan el voltage en la bateria y no comparan con la salida del alternador. Puede haber caida de tension en el positivo y en el negativo los manuales indican que lo maximo que se debe de perder en el camino del alternador a la bateria es 0.3v. y una bateria defectuosa hasta te puede subir el voltaje del regulador, a mi me paso una vez cambie 2 reguladores porque me pasaba de 15v la carga y se estabilizo a 14v hasta que probe con otra bateria. la bateria tambien es un estabilizador de voltage en el sistema de carga. por eso no se debe desconectar una bateria con el motor andando, se eleva el voltage y puedes quemar la ECU.

Por favor, Conectar o Crear cuenta para unirse a la conversación.

- manual-mecanica

- Autor del tema

- Fuera de línea

- Fresh Boarder

-

Menos

Más

- Mensajes: 2

- Gracias recibidas: 5

14 años 2 meses antes - 14 años 2 meses antes #28321

por manual-mecanica

Respuesta de manual-mecanica sobre el tema Re: Alternador que no carga

Muchas gracias, voy entendiendo, si sabía que a mí lo de las escobillas no me cuadraba ( choto, carbon te refieres a la escobilla verdad ? ), entonces, os paso un esquema de lo que he medido con el tester, yo creo que eso es así seguro, lo de la escobillas del negativo lo dejo, la del positivo no, porque es que viene directo de la tuerca donde se conecta el cable positivo, lo he puesto en el esquema, conectado al conector 1, (os pongo una foto tb:

Terminales 2, y 3 son los del conector doble, el 2 como veis va directo a un fusible de la cajita de al lado de la bateria, y directo a positivo de bateria. ESte esta marcado con LG en un libro de taller de un micra posterior, el del motor K12, el mio es el K11, y el otro, el 3 viene marcado como Lque vá al regulador, y veo del regulador al panel de pasa por el fusible de 10A debajo del volante, y luego va a la llave de contacto.

Lo que no entiendo como 2 terminales del conector a una escobilla, la negativa, (o menos positiva) ...........

Los diodos, no no están sueltos, si los 3 diodos los he medido desde el final de cada la fase hasta la misma tuerca del conector 1. Y los otros 3 desde un esparrago roscado, por la que luego pasa la tapa, osea negativo, hasta los los mismos extremos de bobinados. El bobinado estatórico tiene conexion en estrella, verifificado.

Entonces, yo creo que el alternador está bien, voy a montar otra vez el alternador, ojala sea una excesiva caida de tensión en los cables claro. Para medir tensión, cual será el cable que carga la bateria la, el gordo del conector 1 (yo creo que si), o el del 2 el LG, que va con uno de 10A ?, porque lo desconecto, arranco, a ver que tensión hay.

El alternador es un HItachi12V65A. A ver si encuentro por Inet el esquema.

El nuevo esquema, la escobilla negativa no conectada, ya que no lo se, ni los conectores 2, y 3, el resto esta bien.

E1 sería una escobilla (directa del positivo de bateria), y la de al lado a la derecha la otra, no se si sabreis como va conectada a terminales 2 , y 3, continuidad no hay, vamos el tester no pita, hay algun componente electrónico intercalado.

Muchas gracias

Un saludo

Terminales 2, y 3 son los del conector doble, el 2 como veis va directo a un fusible de la cajita de al lado de la bateria, y directo a positivo de bateria. ESte esta marcado con LG en un libro de taller de un micra posterior, el del motor K12, el mio es el K11, y el otro, el 3 viene marcado como Lque vá al regulador, y veo del regulador al panel de pasa por el fusible de 10A debajo del volante, y luego va a la llave de contacto.

Lo que no entiendo como 2 terminales del conector a una escobilla, la negativa, (o menos positiva) ...........

Los diodos, no no están sueltos, si los 3 diodos los he medido desde el final de cada la fase hasta la misma tuerca del conector 1. Y los otros 3 desde un esparrago roscado, por la que luego pasa la tapa, osea negativo, hasta los los mismos extremos de bobinados. El bobinado estatórico tiene conexion en estrella, verifificado.

Entonces, yo creo que el alternador está bien, voy a montar otra vez el alternador, ojala sea una excesiva caida de tensión en los cables claro. Para medir tensión, cual será el cable que carga la bateria la, el gordo del conector 1 (yo creo que si), o el del 2 el LG, que va con uno de 10A ?, porque lo desconecto, arranco, a ver que tensión hay.

El alternador es un HItachi12V65A. A ver si encuentro por Inet el esquema.

El nuevo esquema, la escobilla negativa no conectada, ya que no lo se, ni los conectores 2, y 3, el resto esta bien.

E1 sería una escobilla (directa del positivo de bateria), y la de al lado a la derecha la otra, no se si sabreis como va conectada a terminales 2 , y 3, continuidad no hay, vamos el tester no pita, hay algun componente electrónico intercalado.

Muchas gracias

Un saludo

Última Edición: 14 años 2 meses antes por .

Por favor, Conectar o Crear cuenta para unirse a la conversación.

- manual-mecanica

- Autor del tema

- Fuera de línea

- Fresh Boarder

-

Menos

Más

- Mensajes: 2

- Gracias recibidas: 5

14 años 2 meses antes - 14 años 2 meses antes #28329

por manual-mecanica

Respuesta de manual-mecanica sobre el tema Re: Alternador que no carga

Mas cosas, como estoy buscando info por la Red, he podido ver que mi alternador utiliza triodos para rectificar de fase a positivo.

Luego por la zona de las escobillas, arriba de los muelles hay un hueco en el que va algo que necesita ser refrigerado, ya que este hueco tiene encima unas aletillas de refrigreracion. Creia que en este hueco estarían los diodos, quizas sean para refrigerar las mismas escobillas, no lo se.

En el mismo alternador, según mi foto, el terminal de arriba del conector lo identifica con letra S , y el de abajo con L.

Un saludo

Luego por la zona de las escobillas, arriba de los muelles hay un hueco en el que va algo que necesita ser refrigerado, ya que este hueco tiene encima unas aletillas de refrigreracion. Creia que en este hueco estarían los diodos, quizas sean para refrigerar las mismas escobillas, no lo se.

En el mismo alternador, según mi foto, el terminal de arriba del conector lo identifica con letra S , y el de abajo con L.

Un saludo

Última Edición: 14 años 2 meses antes por .

Por favor, Conectar o Crear cuenta para unirse a la conversación.

Últimos Manuales