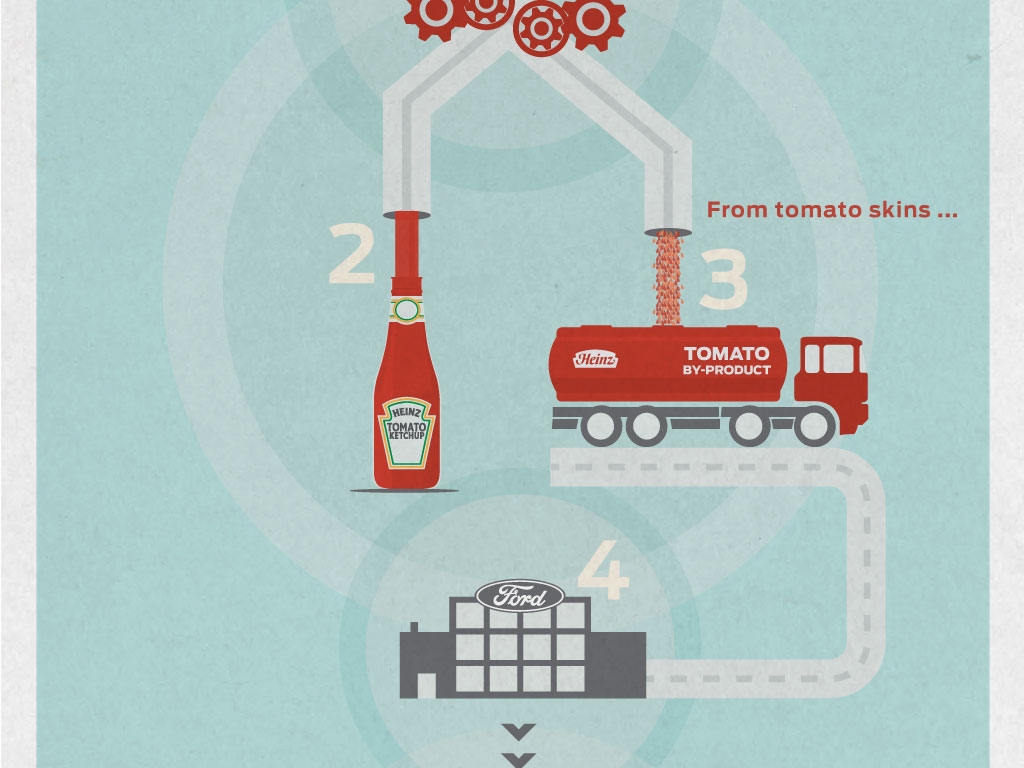

For two years, Ford and Heinz researchers are investigating the use of tomato fibers in the development of sustainable materials for use in vehicle manufacturing. The skin of dry tomato could become a future in wiring or compartments to store coins and other small objects in Ford cars.

"Our goal is to develop a strong and light material that meets the needs of vehicles, while the global environmental impact is reduced." Researchers seek to develop a 100% vegetable plastic, which can be used throughout the vehicle, from the fabric to packaging and with a lower environmental impact than oil -based packaging materials that are currently used. "Although we are in the early stages of the investigation, and many questions remain, we are excited about the possibilities that this could produce."

Ford's commitment to reduce, reuse and recycle is part of the company's global strategy to reduce its environmental footprint. In recent years, Ford has increased the use of recycled non-metallic and biological materials, such as fiber-reforted cellulose used in console components and rice shell hoods used in the electrical system, as well as composite materials achieved from coconuts, recycled cotton for carpets and cloth seats or cushions and pmpsacabezas of soy foam.